Services

High Pressure Testing and Pumping Services

High Pressure Testing and Pumping includes the following services:

-

Casing/Tubing Testing

-

Testing and Pumping Services

-

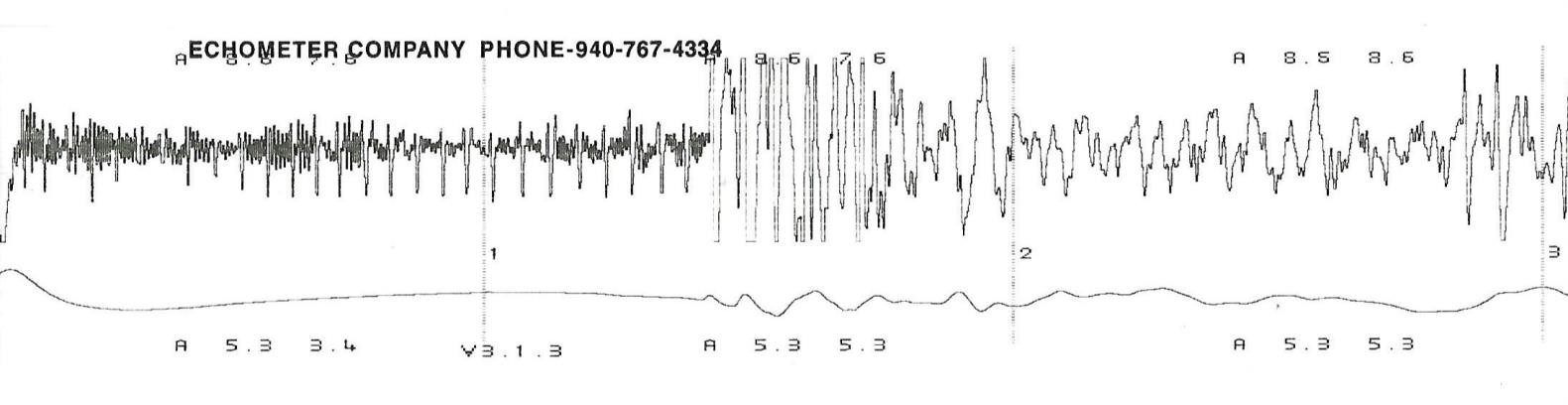

Fluid Level Test

-

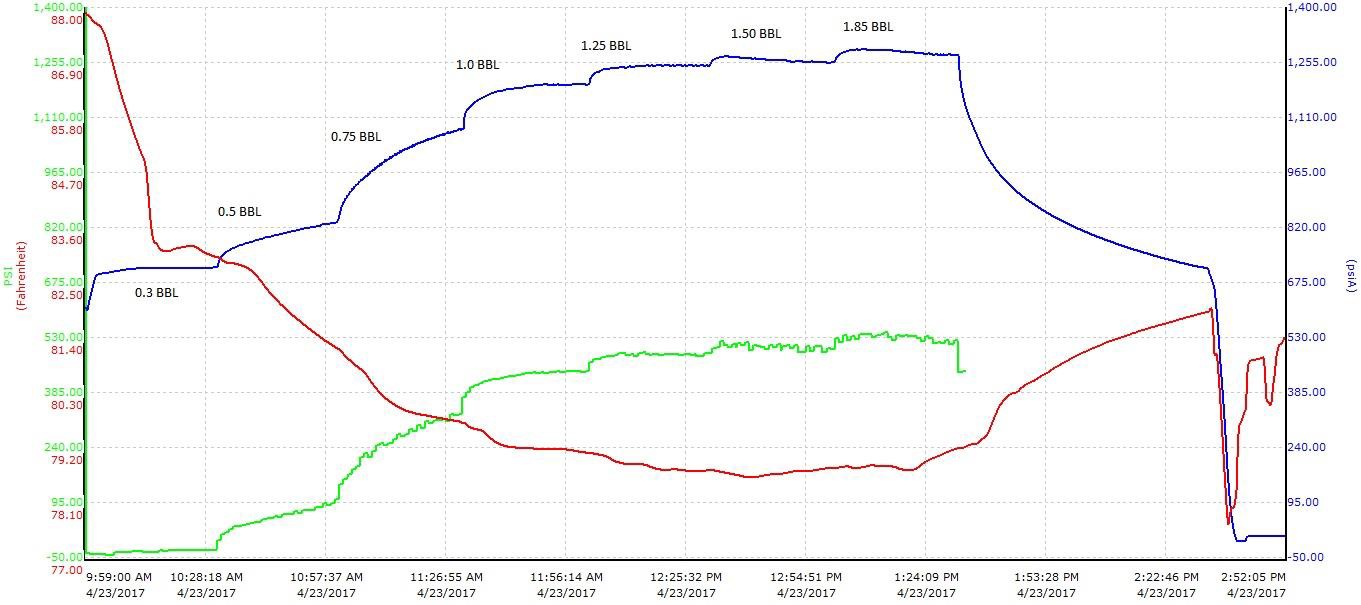

Step Rate Test

-

SandJet Perforating/Cutting

-

HyperClean Jet Washing

-

High Pressure Liner Wash Tools

-

High Pressure Wash Nozzles

Casing/Tubing Testing

Our two newest Hydrotesting units capabilities are listed below as well as some of the newest features and technology advances.

- Bar Tools/ Drag Tools (2 3/8″, 2 7/8″, 3 1/2″, 4 1/2″)

- We can also test 2 7/8″ and 3 1/2″ poly tubing from 0-10K PSI

- Master Valves

- Hard Line/Flow Line Testing

- Casing testing

- Packer settings

- Roll Right Triplex pump

- 1″ Plungers

- 1 1/2″ stroke

- 21GPM @1200RPM

- 12,000 PSI maximum testing pressure

- Relief valve set @8000PSI

- Each unit is equipped with standard testing tools.

- All the bar tool mandrels are manga flux tested every six months and drag tool rods are replaced every six months

- All hydrotesting can be recorded with a chart from pressures starting at 0- 10,000 PSI

Testing and Pumping Services

- Fluid level test (fluid level shots) mainly for idle wells.

- Pressure tests for: the casing, tubing, with a liquid. Injection tests.

- All in one combo: BPV – Two-way check valves -Testing – Lubricate – Slick line services – Plug setting -Wellhead Valve Change Outs – Hydraulic wrenches nipple up / nipple down – Tubing / CIT testing -Pressure testing – Pumping services.

- Real time surface and downhole pressure recording. Bottom hole pressure recording.

- Step rate test.

- Lap test.