SANDJET PERFORATING / CUTTING SERVICE

Overview

-

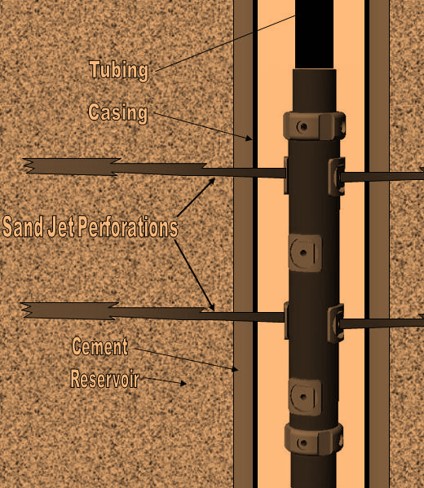

This is a downhole tool that uses high pressure abrasive fluids to perforate the casing, cement, and extend a cavity into the reservoir.

-

Can perforate through several strings of casing cement. Once it reaches the formation, the total target penetration increases with time which also depends on the formation type.

-

After the perforation, a stimulation can even expand more the penetrated area.

SJP well schematic with tool

Actual case study of a SandJet test

Sandjet Perforating and Cutting: Features and Benefits

The SandJet eliminates the risk of using explosives and offers added convenience of perforating multiple holes without pulling out of the hole, no “reloading”. The SandJet unit can be deployed with jointed pipe and coil tubing.

Not only can it cut through different sizes of tubing and/or casing, it can also perforate through multiple strings, which makes it a cost-effective and safer alternative. Unlike explosives, the SandJet is not affected by temperature.

-

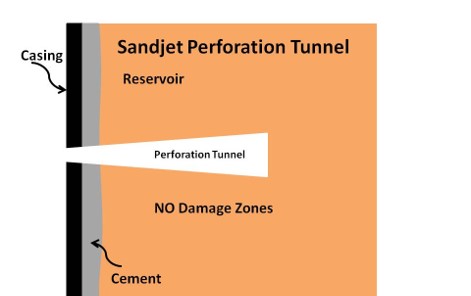

Extends efficiently into the reservoir by eroding the perforation channel.

-

Washes out a tunnel with a larger inner diameter for increased contact with the formation- 1 inch to 2 inches diameter tunnel.

-

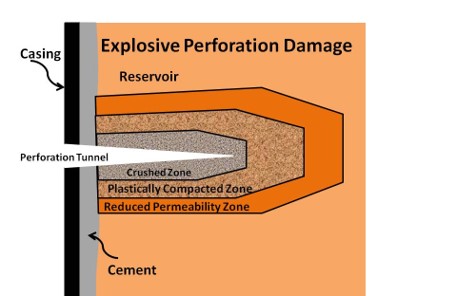

Eliminates compressive stresses on source rock.

-

Better reservoir drain area.

-

Doesn’t damage the formation.

-

Explosive guns leave a crushed zone, debris (iron oxide and metallic), reduce the permeable zone, and damage the formation.

-

The tool Body Can Be Used in Multiple Casing Sizes

-

Available in Many Phasing Patterns, 60°,90°,120°, 180°.

-

Multiple Shot Density Configurations- shots per foot include 2 spf to 9 spf and more if desired.

-

Can be run on coiled tubing or jointed pipe.

-

Can be used in multiple OD sizes, can pass through tight restrictions.

-

No explosives are necessary for the process. SJP is safer than conventional tubing conveyed, and wireline conveyed explosive methods.

-

No government permits or military escorts required.

-

Uses only sand, water and gel to cut holes.

-

It handles high pressure pumping, personnel is trained to setup, test the equipment, and perform the job safely..

-

The SandJet eliminates the risk of using explosives and offers added convenience of perforating multiple holes without pulling out of the hole, no “reloading”.

-

The SandJet unit can be deployed with jointed pipe or coil tubing.

-

It uses sand pumped at high pressure introduced downstream separately of the fluid pump, through the pipe and exits at the perforating nozzles to either cut the pipe/casing or perforate two to eight holes per foot.

-

Not only can it cut through different sizes of tubing and/or casing, but it can also perforate through multiple cemented strings, which makes it a unique cost effective and safer alternative.

-

Unlike explosives, the SandJet is not affected by temperature.

-

The entry hole can vary according to the nozzle size used.

-

The total target penetration can vary depending on the additional time taken at the perforation point.

-

There are different nozzles used to cut casing/tubing where the position is important for an effective cut.

-

SandJet can be used as an abrasive wash to clean casing and tubing. This application is commonly used for disposal wells.