Services

Well Intervention Services

WHAT OUR TECHNOLOGY AND EXPERIENCE CAN DO FOR YOUR BUSINESS?

Titan Oil Field Services provides the equipment and highly trained operators to complete a wide range of well integrity and intervention solutions, including:

SUMMARY OF WELL INTERVENTION PRODUCTS AND SERVICES

- Full line of Coil Tubing tools for 1”-2 7/8” coil:

- Bow spring and fix blade centralizers.

- Knuckle joints.

- Weight bars, and bypass bars.

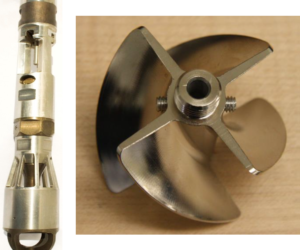

- Mud motors from 1-11/16 up to 4-3/4 and larger sizes on request. 5” 600F DHM for Geothermal wells.

- Dual Flapper Check Valve Disconnects Circulating subs.

- Motor head assembly.

- Standard bits and custom-made mills.

- Packers – mechanical / inflatable on wireline or thru tubing.

- Retrievable / permanent Bridge plugs.

- Cement retainers.

- Scrapers tubing / casing. 2 3/8” – 9 5/8”.

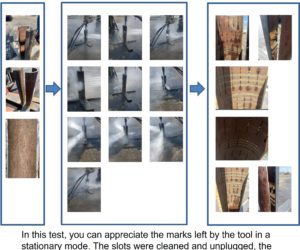

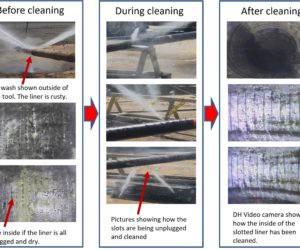

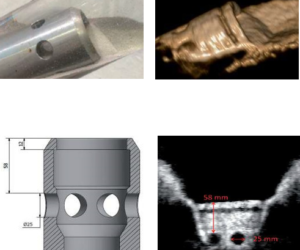

- High pressure rotary jetting and wash tools. Custom made nozzles for clean outs and liner jetting.

- Cup wash tools with custom spacing.

- Capillary tubing services.

- Fishing tools:

o Jars / intensifiers, over-shots, spears, bumper subs.

o Releasable GS and JDC fishing tools.

o Continuous coil cutter overshot.

- All in one truck service:

- BPV – Two- way check valves – Testing-Lubricate.

- Slick line services plug setting/ removal.

- Wellhead Valve Change Outs.

- Hydraulic wrenches nipple up / nipple down Tubing / CIT testing.

- Pressure testing.

- Casing /Tubing – Hydro-testing services:

- Standard testing tools.

- Bar tools and drag tools: 2 3/8″, 2 7/8″, and 3 1/2″. 4 1/2” tools are available by request.

- Roll Right Triplex pump.

- 1″ Plungers, 3″ stroke.

- 21GPM @1200RPM.

- Relief valve set @8000PSI. Adjustable

- SandJet perforating /Cutting service

- HyperClean Jet Washing Service

- Dog Cutter and Valve Drilling Service

- Rappic Service

- RA. Tracer-Noise-Pressure Tests

- Pressure Pumps. Injection Test-Plugs/Packers setting/ test-COMBO

- Down Hole Video Service.

- Downhole cameras of ¾”, 1 ¾”, 3“200F.

- Slick Line Services:

- Tag for fill.

- Bailing.

- Tubing plugs (profile & other). Setting and retrieval.

- Fishing

- Gauge rings.

- Mech/hydraulic tubing punch.

- Gas lift.

- Memory surveys (PT and Well Integrity).

- Long term BHPT monitoring.

- Down-hole specialty logging tools in memory mode.

- Braided Line Services:

- Heavy duty fishing and jarring applications.

- Swabbing.

- Jet pump recovery.

- Oil/Gas and Geothermal cased-hole memory surveys.

- Mechanical packer set / removal.

- Single / long term monitoring.

- E-Line Services (Memory, CT, or SRO):

- Oil/Gas, water & Geothermal logging.

- Radioactive tracer, Noise log, Spectral Noise, Ultrasonic Leak Detection, Well Integrity logging. with Read Cased Hole.

- PTS GR CCL (662 F), PT for TO wells, Temp.

- Multi-finger caliper (MFC) of 24, 40, 60, and 80 arms. HT MFC 430F. X-Y Caliper.

- Cement Bond, Ultrasonic Imaging, Electromagnetic Thickness, ultrasonic Thickness, inclinometer, accelerometer.

- Pulsed Neutron (waterflow log). LAP Test, Step Rate Test.

- Viper Drilling service:

- Cordax LWT service:

- Open hole triple combo.

- Tools can be run in cased hole: CNL-GR-CCL .

- Nitrogen Gun for Cleaning

- Well Intervention / Workover Rigs

In addition to the Intervention services, Titan also offers a wide selection of Wellhead maintenance, well cleanouts, milling and drilling, whipstock tools, fishing tolls, tubing punchers, plug and packer setting.

We Partner with Cordax in Openhole and Cased hole logging services. LWT logging while tripping using resistivity gamma, neutron and density tools. Those tools can be run using slickline in memory mode.

We work in partnership with world-leading logging specialist, READ Cased Hole to offer a wide range of well integrity services to US operators.

We partner with Viper Drilling which mechanically drills 1″ horyzontal wells.