Services

HyperClean Jet Washing

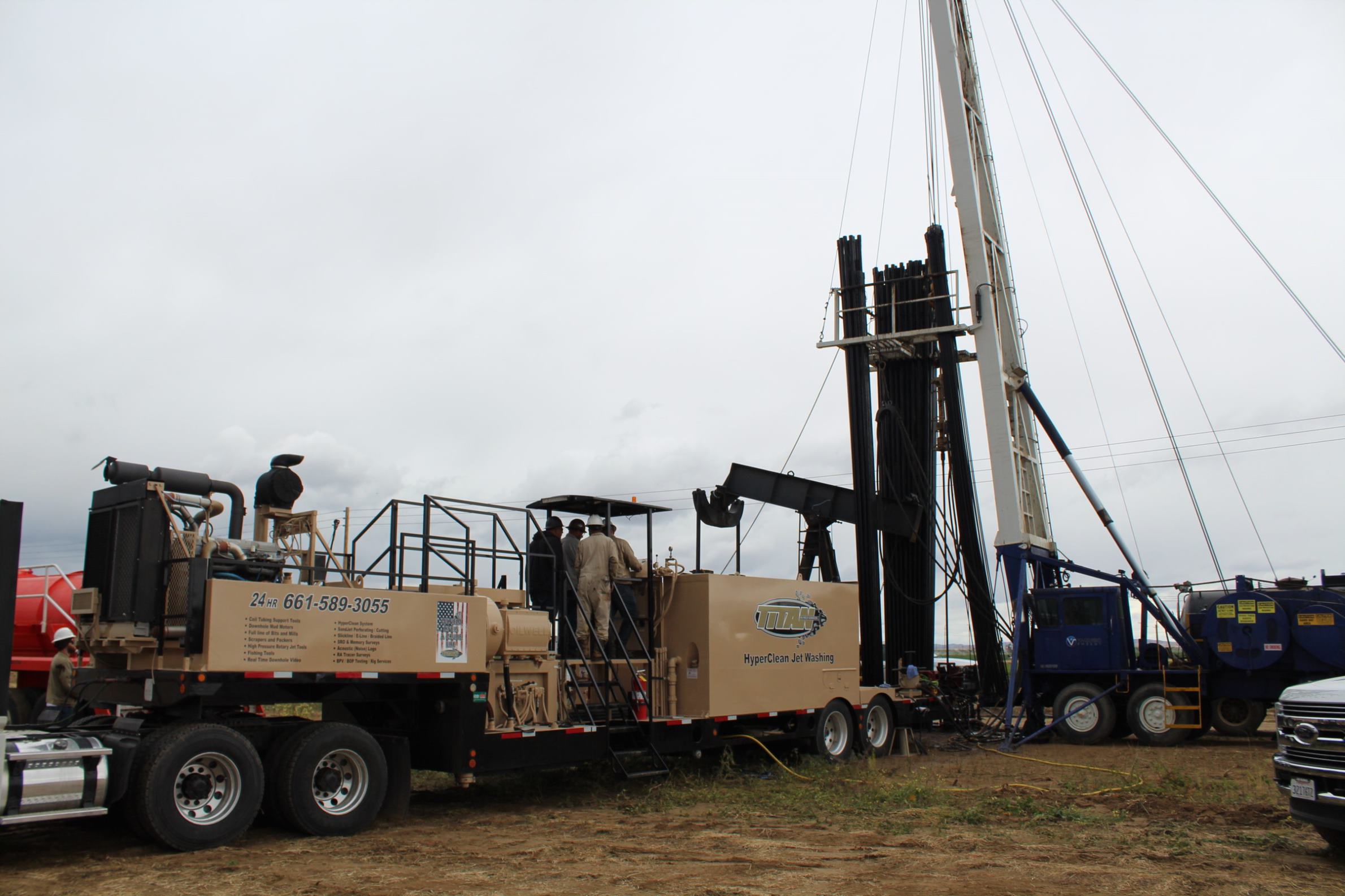

On February 24th 2021, we rolled out our HyperClean Jet Washing unit with resounding success!

HyperClean Jet Washing features

- This service consists in pumping fluids at high pressure (7,500 psi).

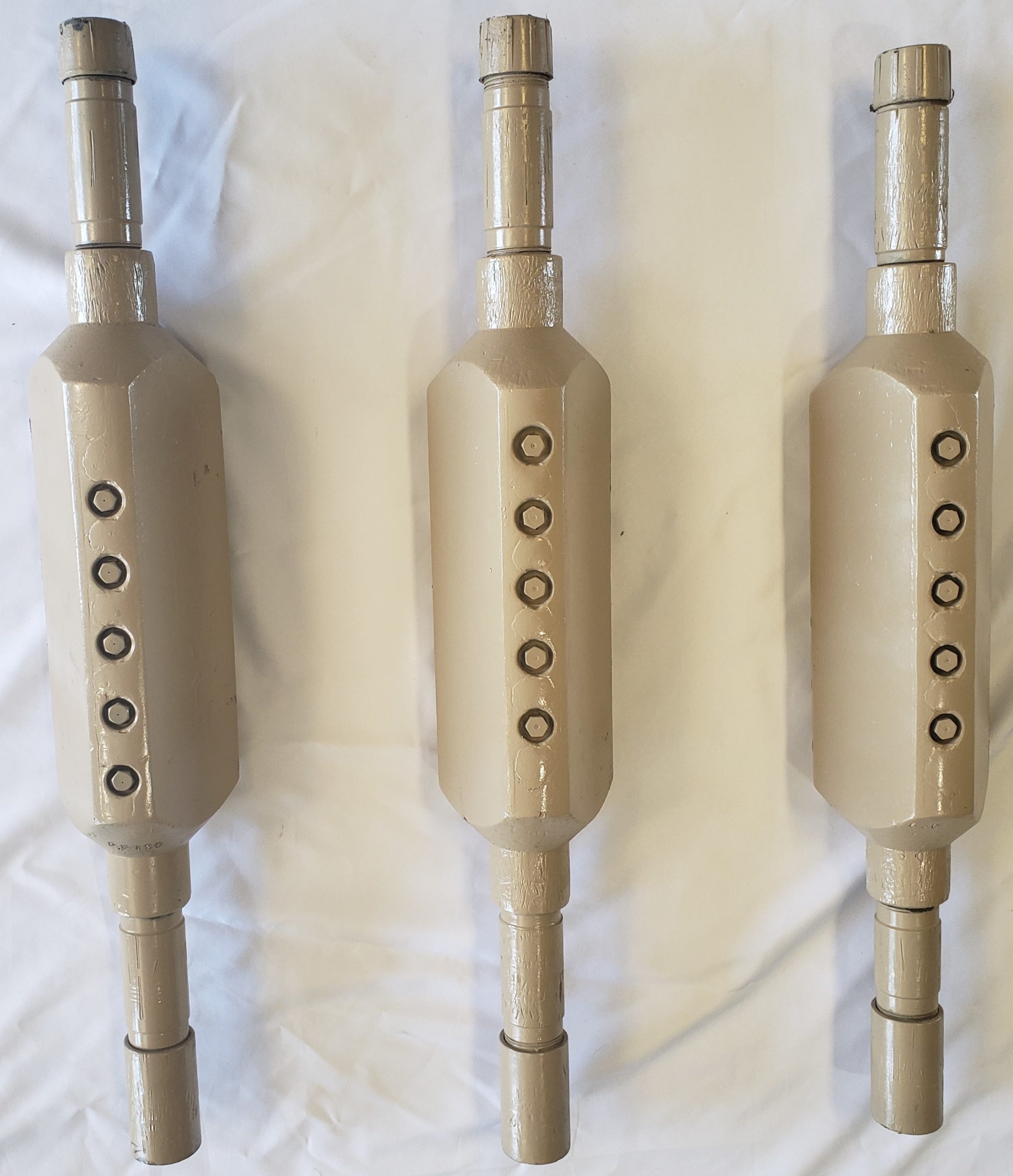

- The fluid is pumped through a string of 1 ¼” tubing down to the jetting tools.

- Three jetting tools can be run one joint apart to wash 96 feet in each pass.

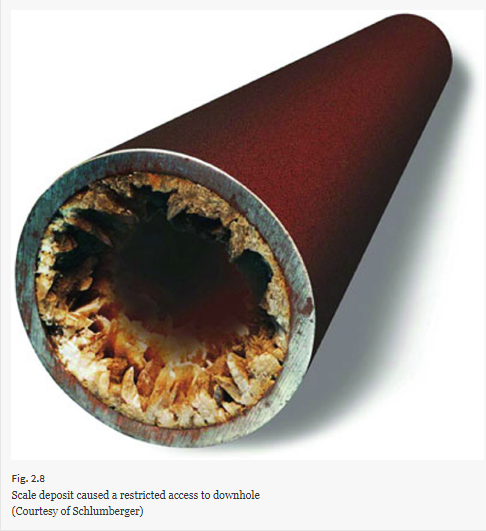

- The HyperClean unit is best suited to clean slotted liners in producing wells, clean perforations, and to clean scale buildup or debris in casing, tubing, or liners.

- The HyperClean Jet Washing service has many additional applications for high pressure cleaning.

- This service is now available. See pictures below.

HyperClean Operation at low pressure

HyperClean Case Study For 5 1/2" Slotted Liner

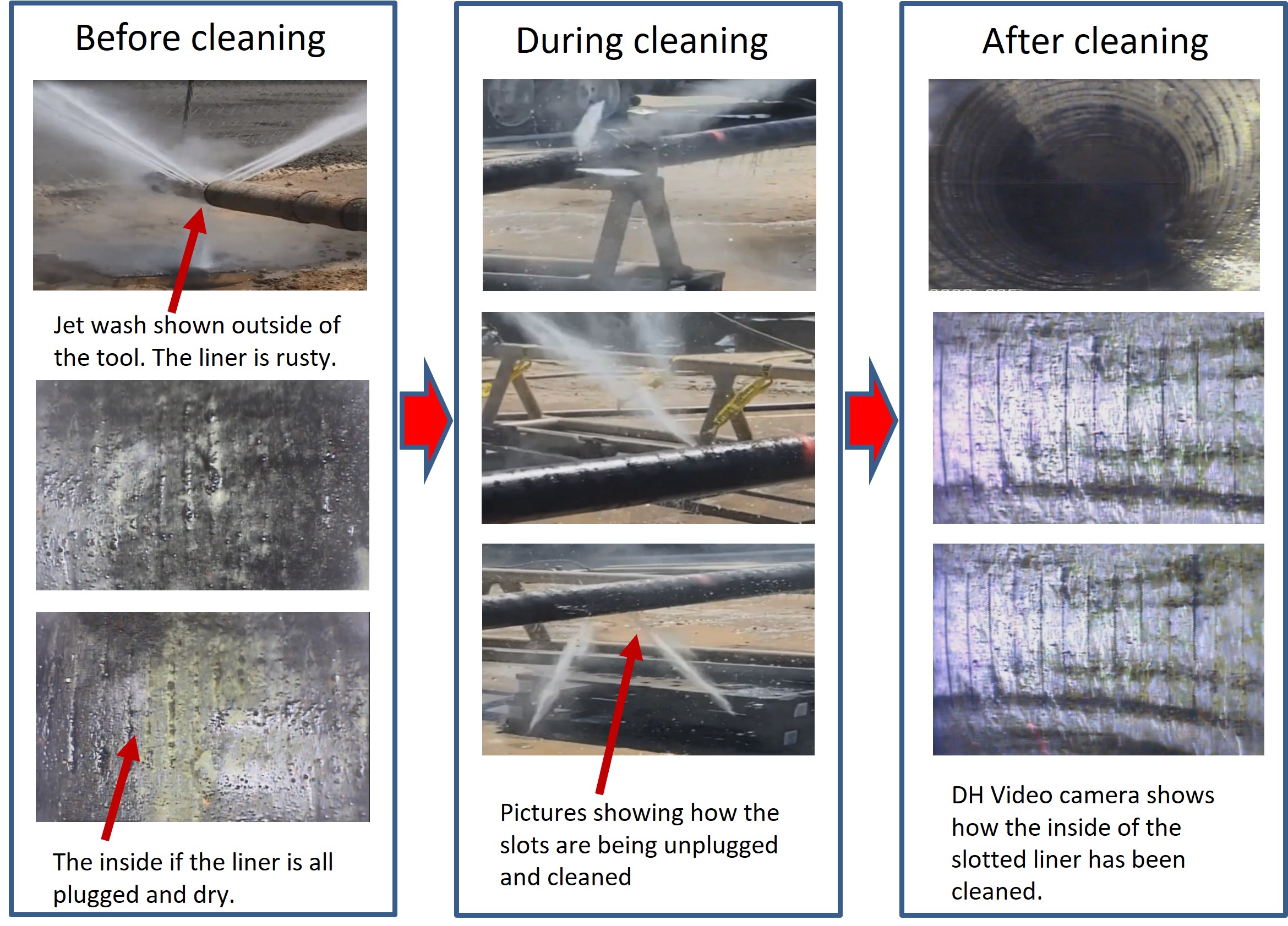

- In May 2021 a shop test was made to clean a 5 1/2″ slotted liner.

- The slotted liner was plugged and rusty which made the conditions harder and more difficult to clean compared to a regular slotted liner under down hole conditions, which are wet and oily.

- We started the test by recording the inside of the slotted liner with a camera to show the conditions of the slotted liner.

- The outside of the slotted liner was rusty.

- We proceeded with the jet washing tool to clean the slotted liner.

- As you can see in the video below the cleaning process was a success, as you watched the holes become unplugged.

- A second video was run to see the inside of the slotted liner after the use of the HyerClean Jet washing tool.

- The slotted liner was clean from the inside and unplugged.

HyperClean Jet washing Case Study

HYPERCLEAN JET WASHING CASE HISTORY

5 ½” SLOTTED LINER TEST

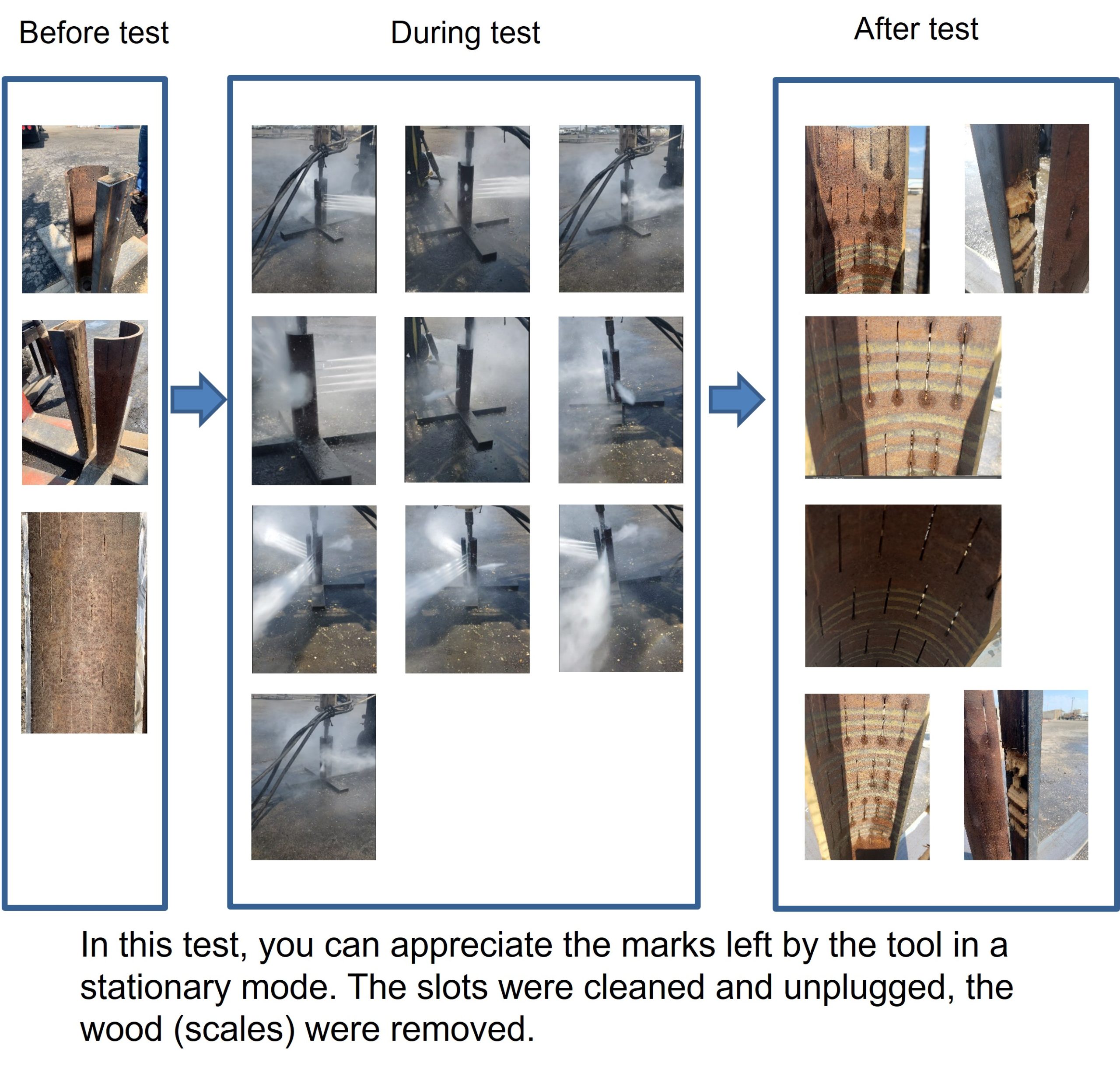

Two tests were made:

-

The first test was made with the tool stationary (no rotation).

-

The second test was made with rotation and moving the tool up and down.

In this test, you can appreciate the marks left by the tool to the liner when the tool moved up and down. The slots were cleaned and unplugged, the wood (scales) were completely removed.